aim Value

With

Outstanding Expertise,

Achieving Goals Together

Outstanding Expertise,

Achieving Goals Together

With unparalleled expertise and a passion for smart manufacturing innovation, aim Systems will

work with you to realize your value and achieve your goals in this digital age.

work with you to realize your value and achieve your goals in this digital age.

Product

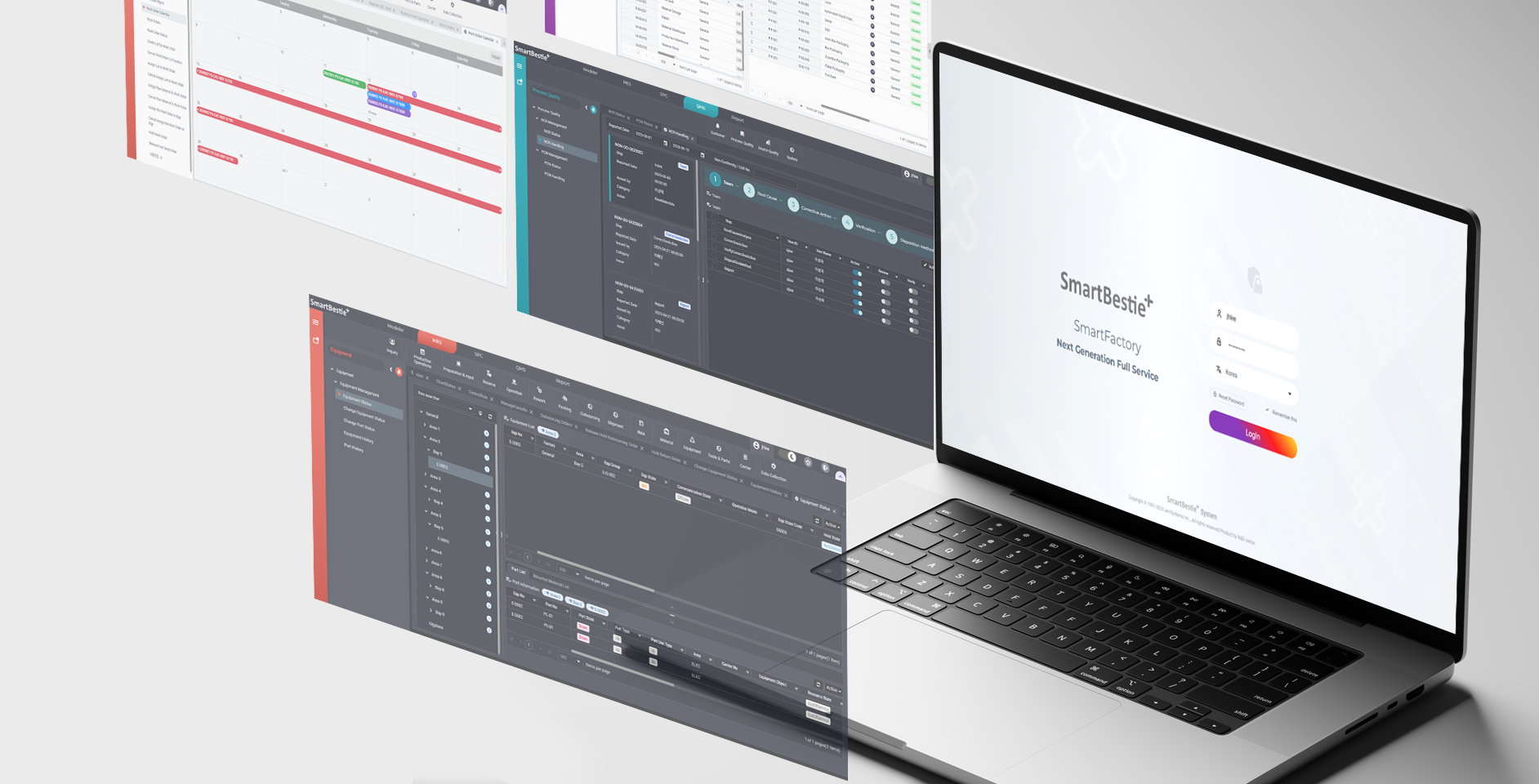

Launch of Advanced MES Solution

Achieve Reduced Factory Operating Costs and Maximized Productivity

Achieve Reduced Factory Operating Costs and Maximized Productivity

Our advanced smart factory solution features a robust architecture, extensive functionality, and configuration-based flexibility.

It enhances efficiency and productivity in smart factory implementation by minimizing manual labor and enabling automation

and standardization—all while maintaining agility for customized client requirements.

It enhances efficiency and productivity in smart factory implementation by minimizing manual labor and enabling automation

and standardization—all while maintaining agility for customized client requirements.

News

aim Systems Participates

in 'AW 2025' Exhibition

Showcasing

the Smart Factory Solution Suite

in 'AW 2025' Exhibition

Showcasing

the Smart Factory Solution Suite

aim Systems, a leader in smart factory software based on 30 years of know-how in the semiconductor and display industries,

has prepared a place to propose smart factory introduction and construction plans through an experience zone and expert

consultant consultation at the AW 2025

has prepared a place to propose smart factory introduction and construction plans through an experience zone and expert

consultant consultation at the AW 2025

News

Delivering ‘Zero-Touch Solutions’

Through a Spirit of Innovation

A Total Solution Provider Leading Manufacturing Innovation

Through a Spirit of Innovation

A Total Solution Provider Leading Manufacturing Innovation

aim Systems offers next-generation automation solutions tailored to each industry and enterprise through its ‘Zero-Touch’ autonomous

manufacturing system. Our innovation DNA is driven by expertise, transparent communication, and a strong sense of care,

setting us apart in the field.

manufacturing system. Our innovation DNA is driven by expertise, transparent communication, and a strong sense of care,

setting us apart in the field.

News

Participation in SMATEC 2024

Showcasing

Integrated Platforms, MES,

and Automation Solutions

Showcasing

Integrated Platforms, MES,

and Automation Solutions

At SMATEC 2024, aim Systems introduced its integrated platform and automation software solutions,

including MES, equipment and logistics automation, as well as its airport customer service platform

and big data analytics solutions for digital transformation.

including MES, equipment and logistics automation, as well as its airport customer service platform

and big data analytics solutions for digital transformation.

Smart Factory

Smart Logistics

Smart Airport

Manufacturing Integration Platform

Business

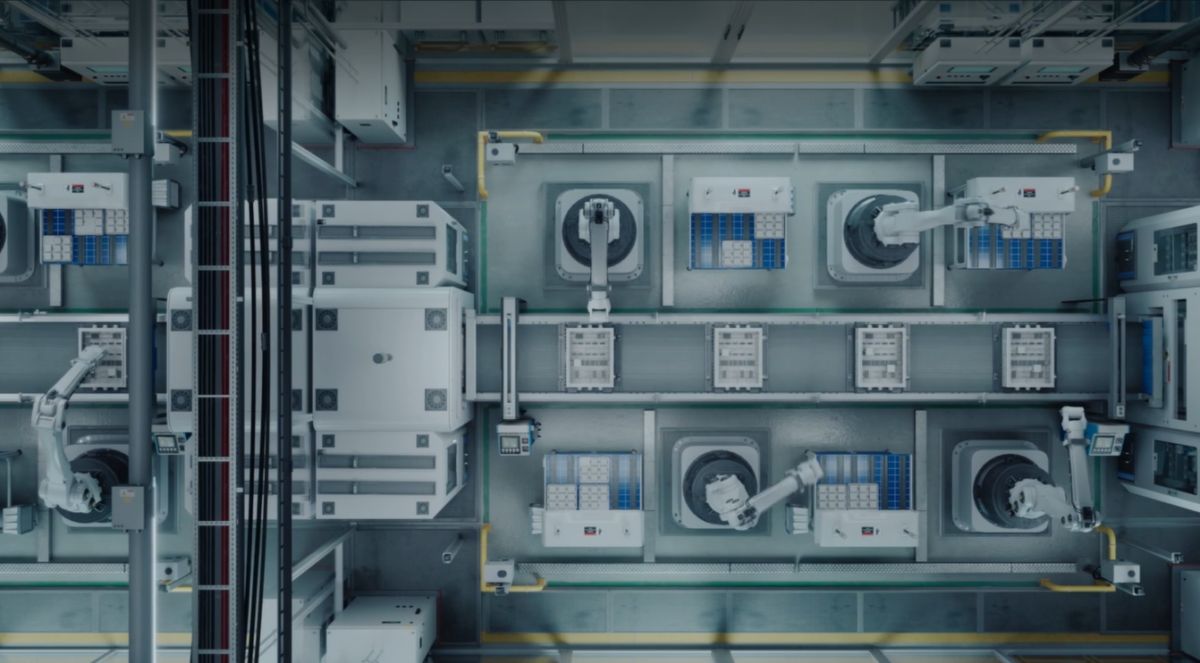

Smart Factory

aim Systems offers smart factory solutions that integrate production execution, facility automation, and logistics automation.

By implementing the entire process from product planning to sales through ICT-based intelligent digital automation, we build an integrated ecosystem of development, deployment, and operations.

By optimizing automated operational processes with data-driven predictions and analytics, we enable the creation of smart factories that are more productive and safer.

By optimizing automated operational processes with data-driven predictions and analytics, we enable the creation of smart factories that are more productive and safer.

제조 분석 솔루션

고객 맞춤형 제품을 생산하는 진화된 공장으로 이러한 과정에 사물인터넷(IoT), 인공지능(AI), 빅데이터 등으로 통합해 자동화와 디지털화를 구현하는 게 기존 공장자동화와 차별되는 요소입니다.

제조 분석 솔루션

고객 맞춤형 제품을 생산하는 진화된 공장으로 이러한 과정에 사물인터넷(IoT), 인공지능(AI), 빅데이터 등으로 통합해 자동화와 디지털화를 구현하는 게 기존 공장자동화와 차별되는 요소입니다.

제조 분석 솔루션

고객 맞춤형 제품을 생산하는 진화된 공장으로 이러한 과정에 사물인터넷(IoT), 인공지능(AI), 빅데이터 등으로 통합해 자동화와 디지털화를 구현하는 게 기존 공장자동화와 차별되는 요소입니다.

Business

Smart Logistics

aim Systems is providing logistics automation solutions for high tech and general manufacturing.

We integrate and manage the automation of logistics facilities in factories, including stockers, OHTs, and AGVs, as well as transportation, inventory, warehousing, materials management, and packaging, while implementing a smart logistics system that incorporates AI, IoT, and robotics.

제조 분석 솔루션

고객 맞춤형 제품을 생산하는 진화된 공장으로 이러한 과정에 사물인터넷(IoT), 인공지능(AI), 빅데이터 등으로 통합해 자동화와 디지털화를 구현하는 게 기존 공장자동화와 차별되는 요소입니다.

제조 분석 솔루션

고객 맞춤형 제품을 생산하는 진화된 공장으로 이러한 과정에 사물인터넷(IoT), 인공지능(AI), 빅데이터 등으로 통합해 자동화와 디지털화를 구현하는 게 기존 공장자동화와 차별되는 요소입니다.

제조 분석 솔루션

고객 맞춤형 제품을 생산하는 진화된 공장으로 이러한 과정에 사물인터넷(IoT), 인공지능(AI), 빅데이터 등으로 통합해 자동화와 디지털화를 구현하는 게 기존 공장자동화와 차별되는 요소입니다.

Business

Smart Airport

aim Systems is creating new value with smart airport automation solutions.

We have developed our own integrated smart airport automation solution, and successfully implemented it at major airports in Korea.

With common-use passenger processing, self-check-in, and self-bag drop systems that comply with IATA international standards, we are streamlining airport operations and enhancing passenger convenience.

With common-use passenger processing, self-check-in, and self-bag drop systems that comply with IATA international standards, we are streamlining airport operations and enhancing passenger convenience.

제조 분석 솔루션

고객 맞춤형 제품을 생산하는 진화된 공장으로 이러한 과정에 사물인터넷(IoT), 인공지능(AI), 빅데이터 등으로 통합해 자동화와 디지털화를 구현하는 게 기존 공장자동화와 차별되는 요소입니다.

제조 분석 솔루션

고객 맞춤형 제품을 생산하는 진화된 공장으로 이러한 과정에 사물인터넷(IoT), 인공지능(AI), 빅데이터 등으로 통합해 자동화와 디지털화를 구현하는 게 기존 공장자동화와 차별되는 요소입니다.

제조 분석 솔루션

고객 맞춤형 제품을 생산하는 진화된 공장으로 이러한 과정에 사물인터넷(IoT), 인공지능(AI), 빅데이터 등으로 통합해 자동화와 디지털화를 구현하는 게 기존 공장자동화와 차별되는 요소입니다.

Business

Manufacturing Integration Platform

An enterprise platform that unifies all phases of manufacturing solutions, from development to operations.

aim Systems drives digital innovation through our manufacturing integration platform that covers all areas of manufacturing, from development to operations.

With its variety of automation modules, ezi empowers developers and engineers to efficiently manage projects. It simplifies data management, web development, business process handling, DevOps, and integrated operations, enabling rapid solution development, deployment, and management to drive innovation.

With ezi, you can maximize efficiency in both development and operational environments.

With its variety of automation modules, ezi empowers developers and engineers to efficiently manage projects. It simplifies data management, web development, business process handling, DevOps, and integrated operations, enabling rapid solution development, deployment, and management to drive innovation.

With ezi, you can maximize efficiency in both development and operational environments.

제조 분석 솔루션

고객 맞춤형 제품을 생산하는 진화된 공장으로 이러한 과정에 사물인터넷(IoT), 인공지능(AI), 빅데이터 등으로 통합해 자동화와 디지털화를 구현하는 게 기존 공장자동화와 차별되는 요소입니다.

제조 분석 솔루션

고객 맞춤형 제품을 생산하는 진화된 공장으로 이러한 과정에 사물인터넷(IoT), 인공지능(AI), 빅데이터 등으로 통합해 자동화와 디지털화를 구현하는 게 기존 공장자동화와 차별되는 요소입니다.

제조 분석 솔루션

고객 맞춤형 제품을 생산하는 진화된 공장으로 이러한 과정에 사물인터넷(IoT), 인공지능(AI), 빅데이터 등으로 통합해 자동화와 디지털화를 구현하는 게 기존 공장자동화와 차별되는 요소입니다.

Solutions & Products

Smart Factory Solution Suite

Manufacturing Analytics Solution

BoostBe+ is an advanced factory solution that produces products which have been tailored to customer needs. It integrates IoT, AI, and big data to enable automation and digitization, going beyond traditional factory automation.

Integrated Automation and Control Solution

Our smart factory platform offers a range of packaged solutions for optimized factory automation, ensuring a smooth and reliable experience from installation to operation.

Integrated DevOps Support Tool

An enterprise platform that unifies all phases of manufacturing solutions, from development to operations.

Customer & Partner

We lead the way in Smart Factory Digitalization through a technology collaboration model with our customers and partners.

Smart Manufacturing Innovation

Digitalization

aim Systems offers smart factory solutions that integrate production execution, facility automation, and logistics automation.

By implementing the entire process from product planning to sales through ICT-based intelligent digital automation, we build an integrated ecosystem of development, deployment, and operations.

By optimizing automated operational processes with data-driven predictions and analytics, we enable the creation of smart factories that are more productive and safer.

By optimizing automated operational processes with data-driven predictions and analytics, we enable the creation of smart factories that are more productive and safer.

News & Event

Check out events and news from aim

![[aim News] aim systems Wins Silver Award at the 2025 Good Design Awards for ‘Incheon International Airport Self Bag Drop’](https://aim.co.kr/wp-content/uploads/kboard_thumbnails/2/202601/696733f069ed65115256.jpg)

![[Press Release] aim Systems Drives Manufacturing Innovation as a ‘Total Solution Provider’ via its Unique 'Zero-Touch Solution'](https://aim.co.kr/wp-content/uploads/kboard_thumbnails/2/202601/69673949bbb938147531.jpg)

![[Press Release] aim Systems Completes Development of Advanced MES, Realizing Reduced Operating Costs and Maximized Productivity](https://aim.co.kr/wp-content/uploads/kboard_thumbnails/2/202601/69673ba0406fa2563458.jpg)